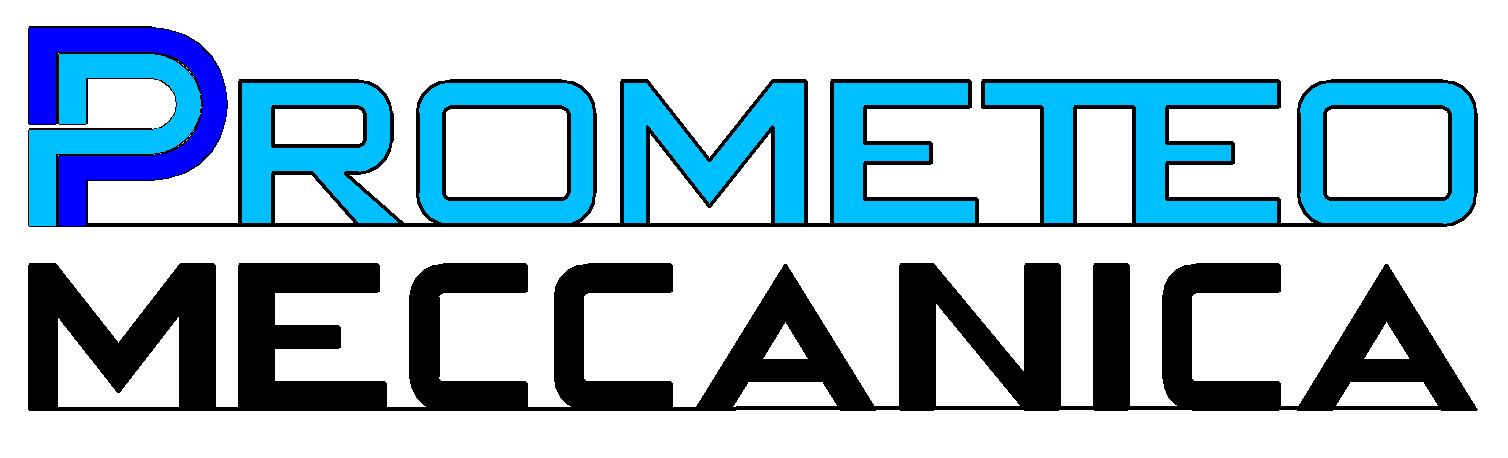

Machines technical verification for an offshore drilling rig

Activity duration : 1100 h

INPUT

Carry out functional and structural verification of drilling winch and mud pump for off-shore drilling rig to be subjected to certification

PROCESS

Analysis of operating and loading conditions, application of norms and standards, FEA of all structural components, specific analytical calculations, first draft of the calculation report, revision of the report after the certification examination

OUTPUT

Calculation report approved by Certification Body

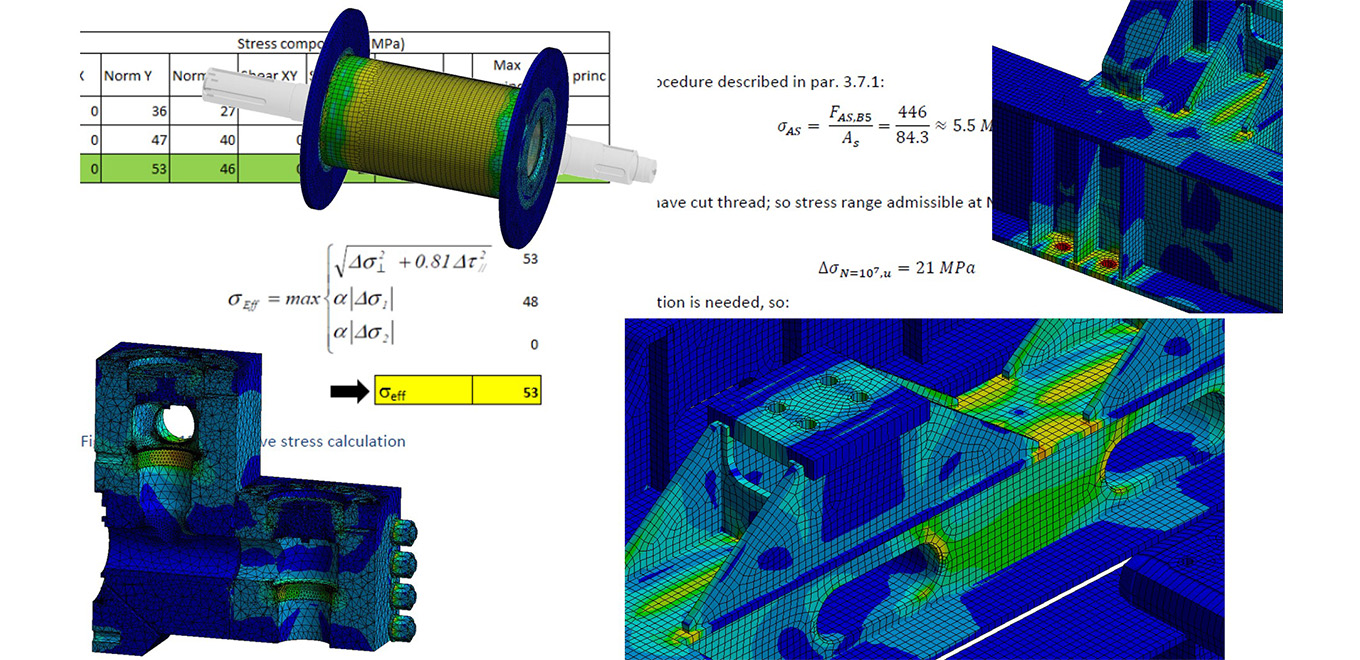

Mud pump new design

Activity duration : 3000 h

INPUT

Making a current production machine lighter and cheaper

PROCESS

Costs analysis of functional assemblies 3D design of alternative proposals to get aims FEA calculation of parts and assemblies Tansmission specialized calculation

OUTPUT

General and detailed arrangement drawings Calculation report

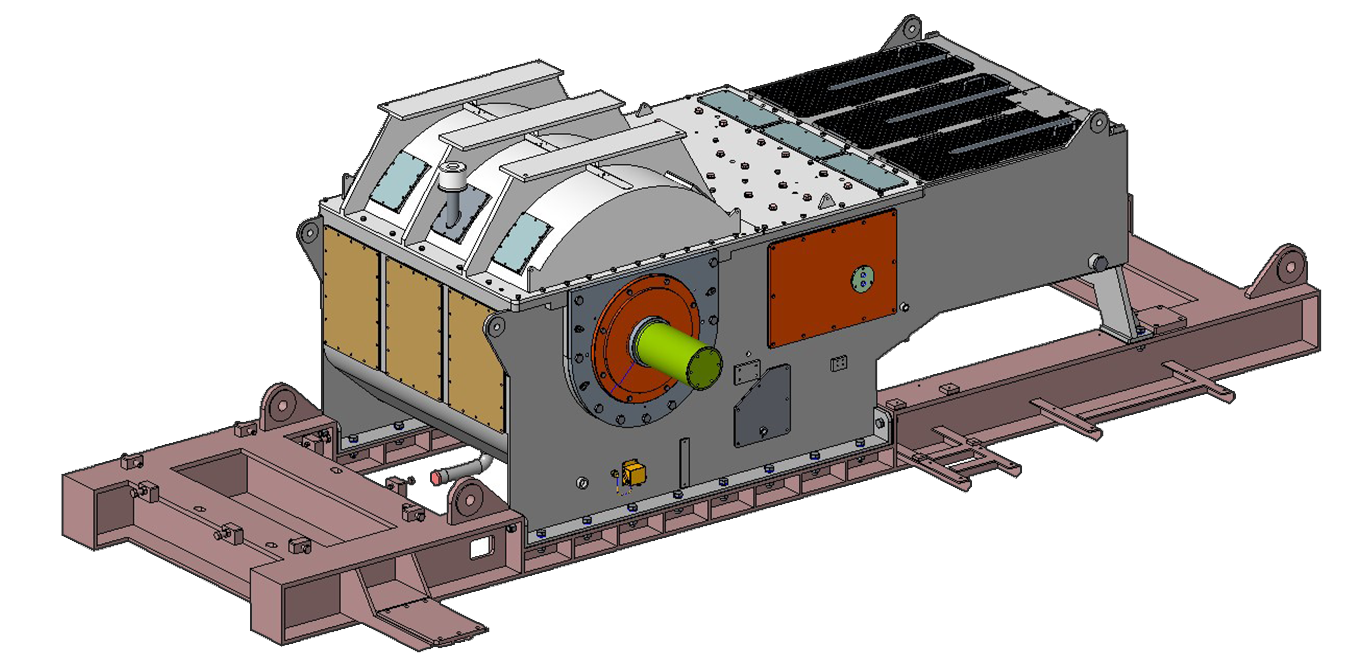

Lubrication system design

Activity duration : 350 h

INPUT

Designing and dimensioning lubricating system for drilling winch

PROCESS

Lubricating needs evaluation Flow and pressure calculation Lubricating system parts detection Layout review on boxes and other parts; 3D modelling of system

OUTPUT

Lubrication scheme with part list 3D model of system

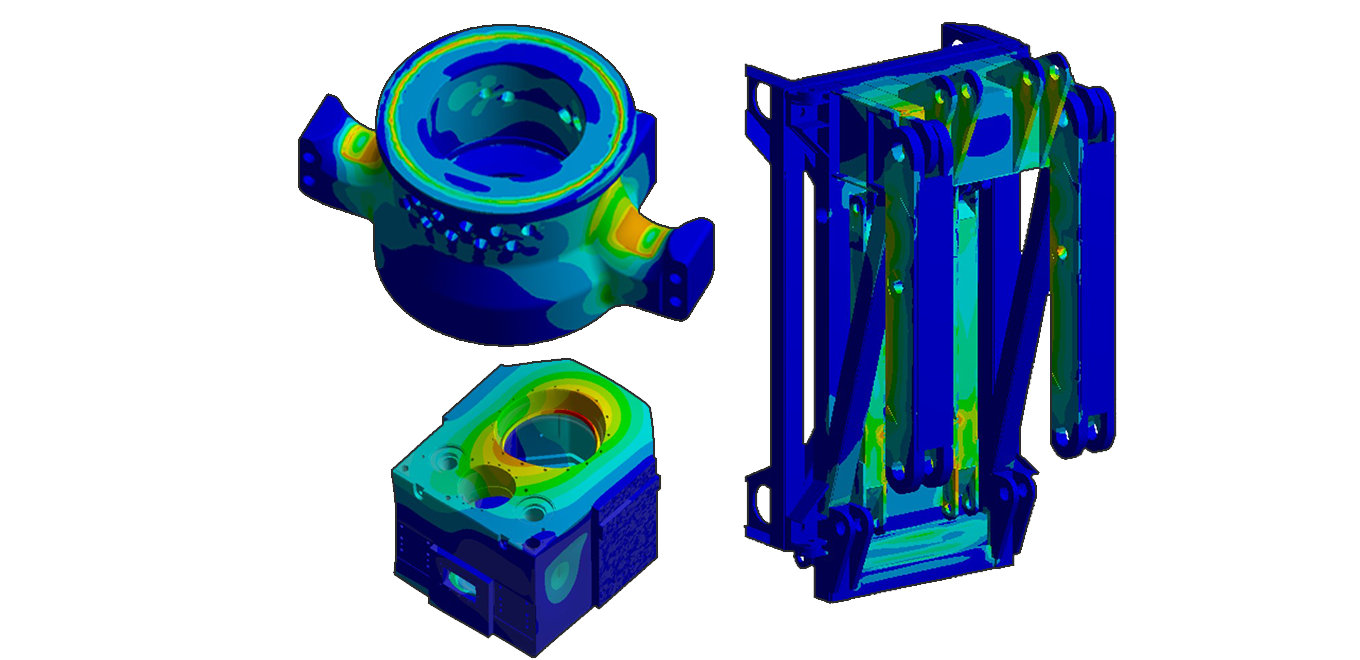

Top drive calculation with API standard

Activity duration : 650 h

INPUT

Calculating a new top drive according to API standard

PROCESS

Functional analysis and load configurations and determination of load configurations FEA calculation on load path and dolly Top drive transmission calculation

OUTPUT

Calculation report

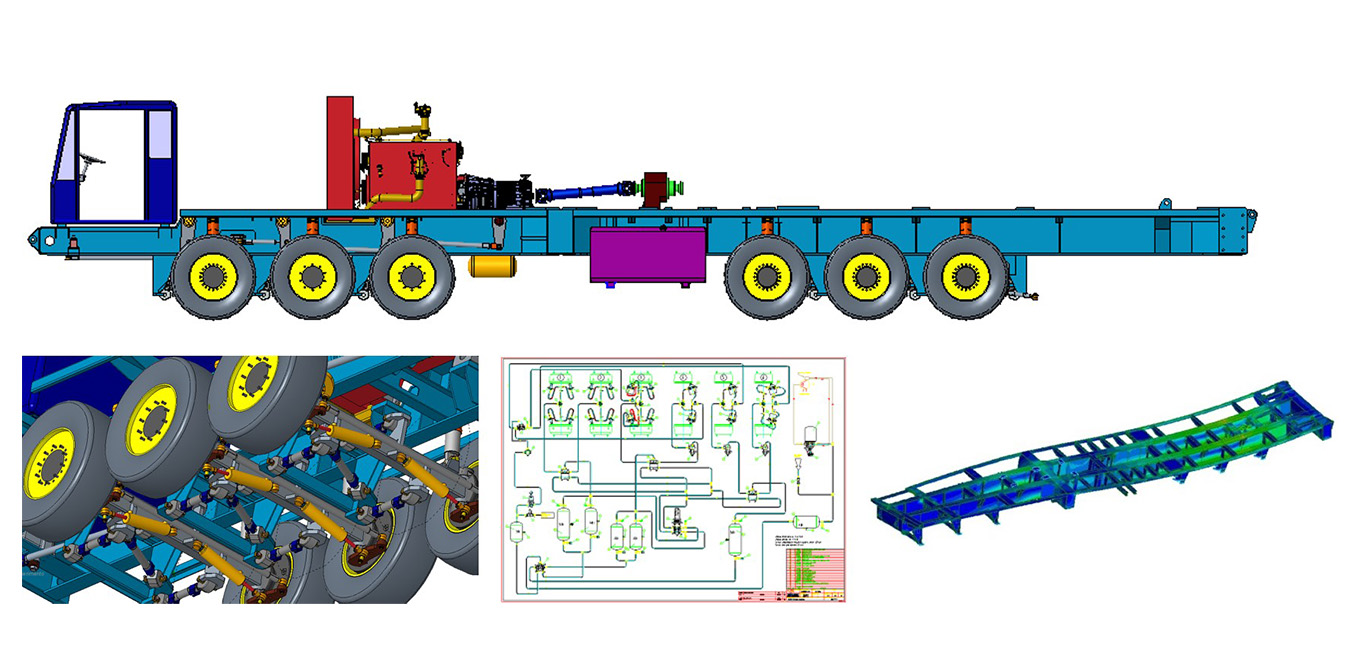

Drilling carrier design

Activity duration : 1600 h

INPUT

Designing a new 6-axle carrier to equip a self-moving drilling machine

PROCESS

Design of frame, steering geometry and transmission FEA calculation of frame and other main parts Specialized transmission calculation Pneumatic and hydraulic system design Electro-hydraulic actuator system design

OUTPUT

Arrangement drawings and calculation report